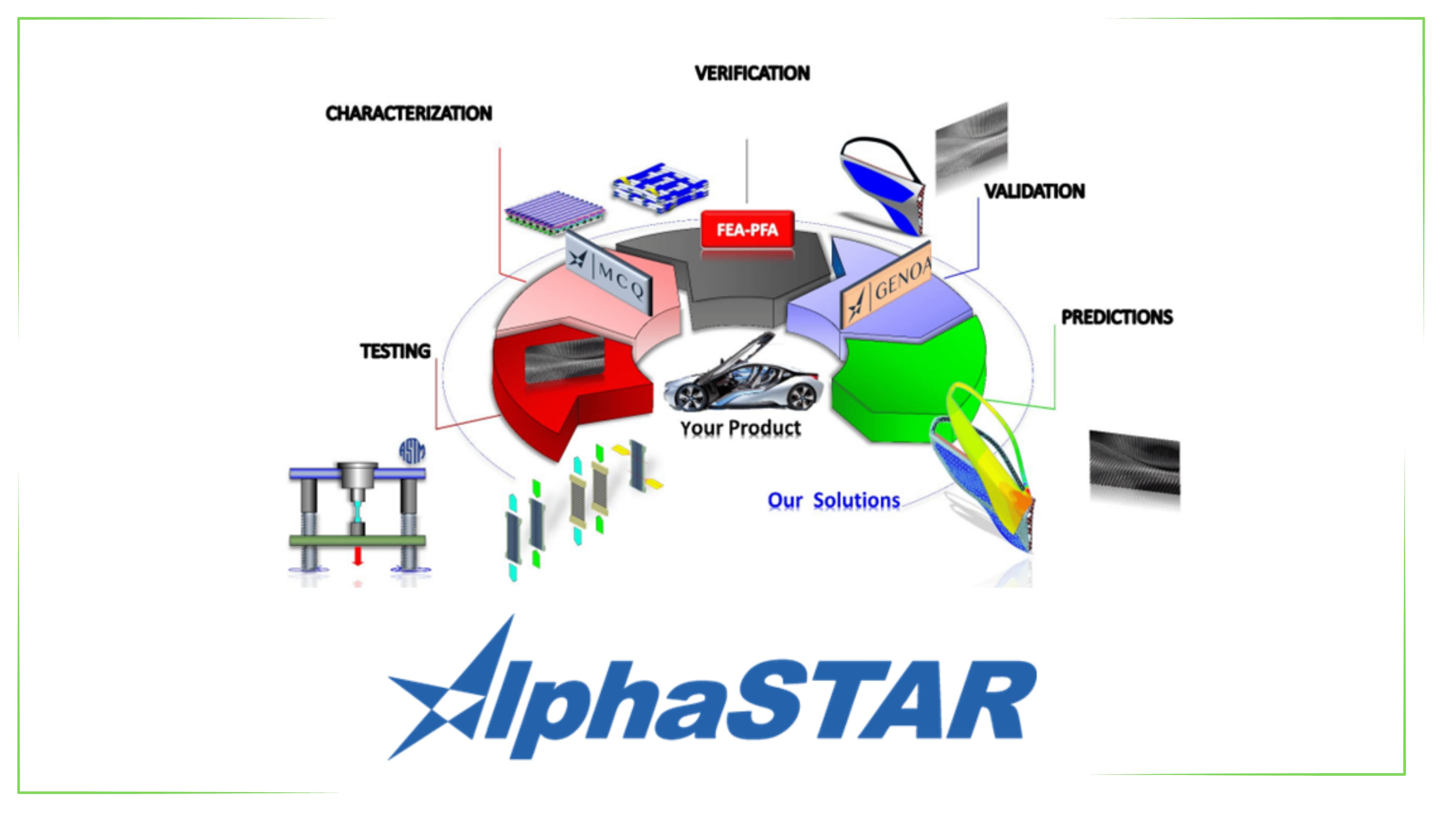

AlphaSTAR Corporation provides innovative physics-based simulation software technologies for additive manufacturing, material modeling and analysis of advanced composites structures in the aerospace, automotive, defense and energy industries worldwide. Offering unique capabilities in fatigue, durability & damage tolerance, our tools will support engineers throughout the design cycle – from experimental testing to end-product fabrication.

AlphaSTAR’s team consists of material scientists, educators, and industy professionals working together to leverage thirty plus years of subject matter expertise in testing, simulation and computational analysis of advanced materials & structures.

MCQ (Material Characterization & Qualification) is the material modeling tool that enables ultra-rapid design and analysis of advanced composite materials, such as continuous & discontinuous PMC, CMC and MMC. MCQ is analytically based utilizing a unit cell approach for assessing material behavior. It models all types of composite architecture, including 2D/3D woven and braided material using multi-scale physics-based micro/macro mechanics formulations. It accounts for “as built” and “as-is” states taking into consideration manufacturing defects, and effect of uncertainties in material properties and specimen geometry. MCQ output can be used as input into finite element solvers such as Abaqus, Ansys, Ls-dyna, NX-Nastran, and MSC-Nastran. Fast, powerful and an easy to use, MCQ is the solution for your material modeling needs.

GENOA is a durability & damage tolerance, progressive failure, and reliability software that provides engineers with predictive computational technology to characterize and qualify advanced composite materials and structures. Through GENOA’s true De-Homogenized Multi-Scale Progressive Failure Analysis, engineers are able to assess failure at the macro, micro and nano levels for advanced materials and composite structures subject to static, fatigue, impact and environmental loadings. Using a closed-form, de-homogenized, analytical methodology, the software is integrated with building block strategies which result in the accurate assessment of failure and test reduction. GENOA’s ability to assess damage, fracture initiation and evolution, integrate the damage & fracture mechanics, and determine percent damage contribution make it a unique tool for advanced structural design

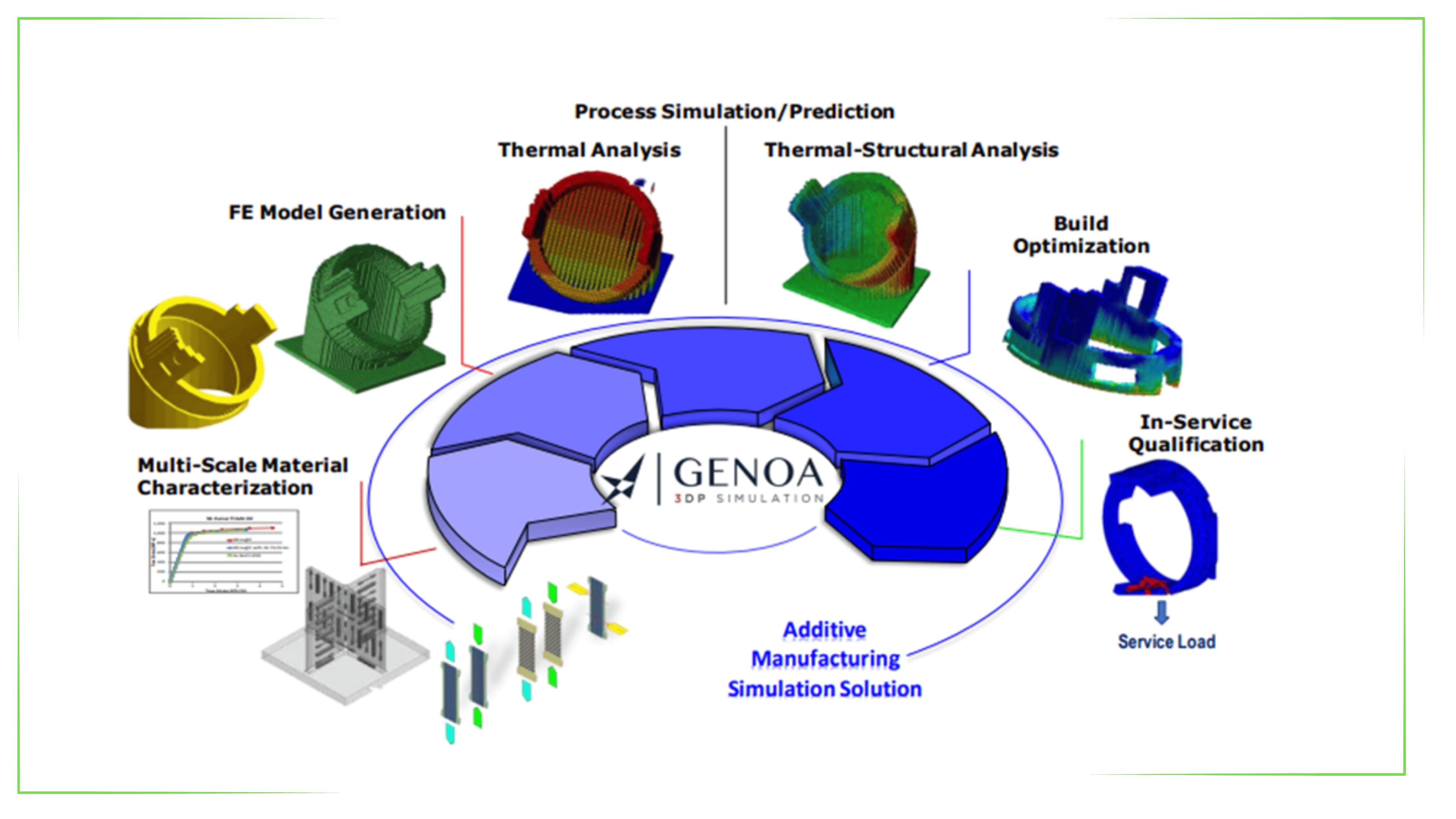

GENOA 3DP Simulation is an additive manufacturing design tool and software suite that simulates the 3D printing process to accurately predict the net shape, residual stress, deformation, damage initiation, and propagation associated with as-built 3D printed parts. Advanced Multi-Scale Progressive Failure (global/local) modeling and analysis methods are used to replicate the entire 3D printing process from the level of Material Characterization to Advanced FE Analysis by either predicting or utilizing manufacturing anomalies, and other irregularities and inefficiencies from micro to macro scales. More significantly, GENOA 3DP Simulation provides the end user with an ability to generate a structural mesh, run analysis and optimize the build in order to reduce weight, reduce scrap rate, improve performance and meet specification.