FE-TECH provides services by fulfilling all the requirements of ISO 9001:2015 standards to develop all kinds of test machines and production machines you need. In addition, it provides perfect service with its competent personnel in issues such as revision of your existing machines and after-sales technical support. Our company, which was established with 100% domestic capital; With its competencies in areas such as mechanical design, analysis, production, software and automation, it develops and commission special products for companies all over the world. With the use of servo hydraulic and pneumatic actuator systems, all kinds of special machines can be developed. In addition, we offer many of our mass-produced products to the domestic and international market.

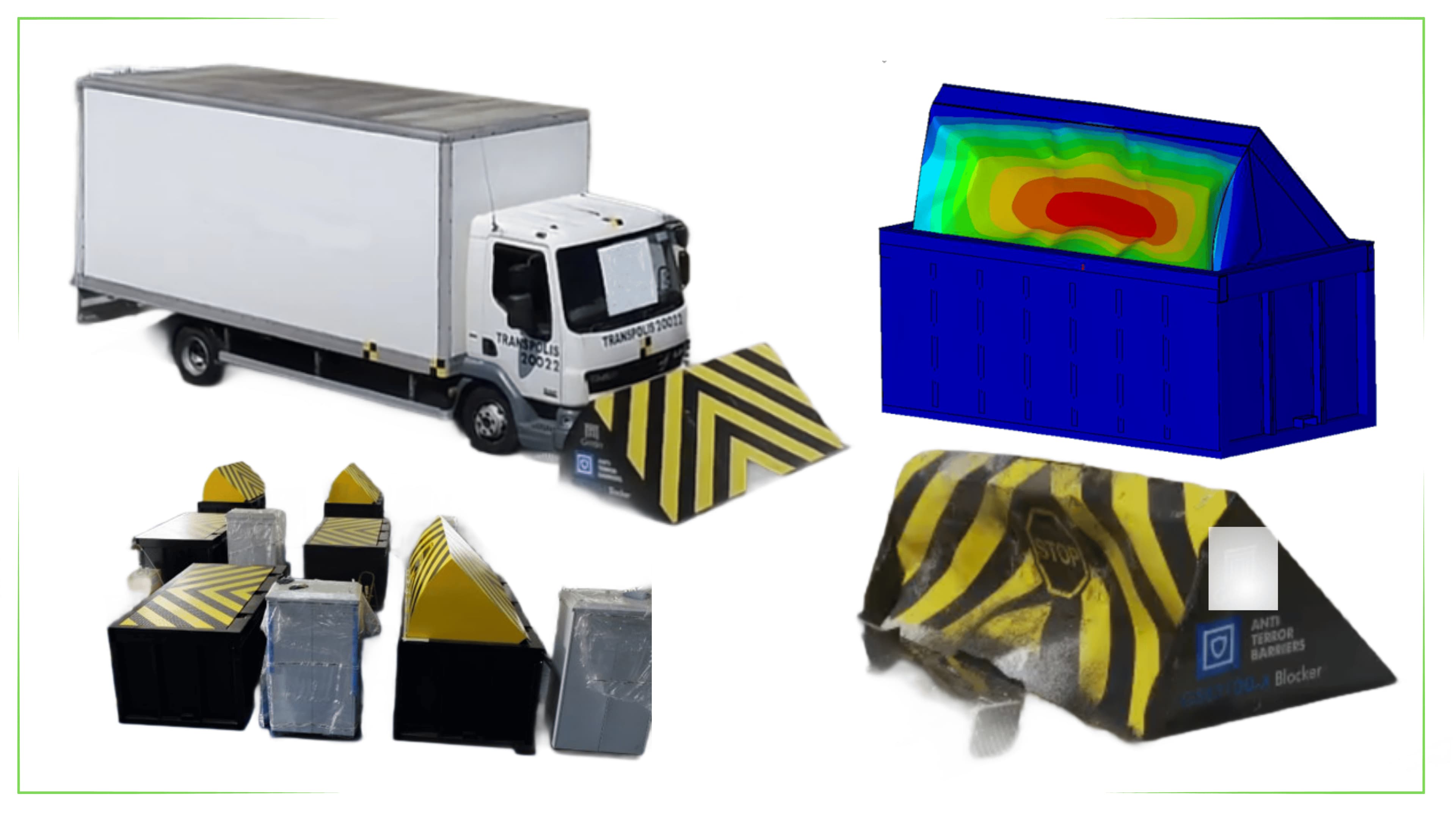

Our self-developed folding arm barrier provides superior protection against vehicle impacts, while at the same time allowing vehicle passage by folding itself back in the event of a collision. This innovative design prioritizes both safety and functionality, making it an ideal solution for parking lots, roadsides and other areas with heavy vehicle traffic.

The production of the Fatigue Loading Machine starts with detailed design and engineering studies, high quality materials are selected and precision machining is carried out with CNC machines. During the assembly phase, hydraulic, pneumatic and electrical systems are integrated, after which all functions of the device are calibrated and tested. Strict quality control procedures are applied throughout the process, ensuring the performance, reliability and precision of the machine. The final product is packaged and delivered to the customer, with installation and training services provided where necessary.

Production of the Bearing Hardness Measuring Machine starts with detailed design and engineering, selecting high quality materials and precision machining with CNC machines. During the assembly phase, hydraulic, pneumatic and electrical systems are integrated and tested, then advanced sensors and control systems are added. The machine undergoes calibration and performance tests and is subjected to strict quality control processes. The final product is packaged and delivered to the customer, with installation and training services provided where necessary. These processes ensure that the machine operates with high precision, reliability and performance.

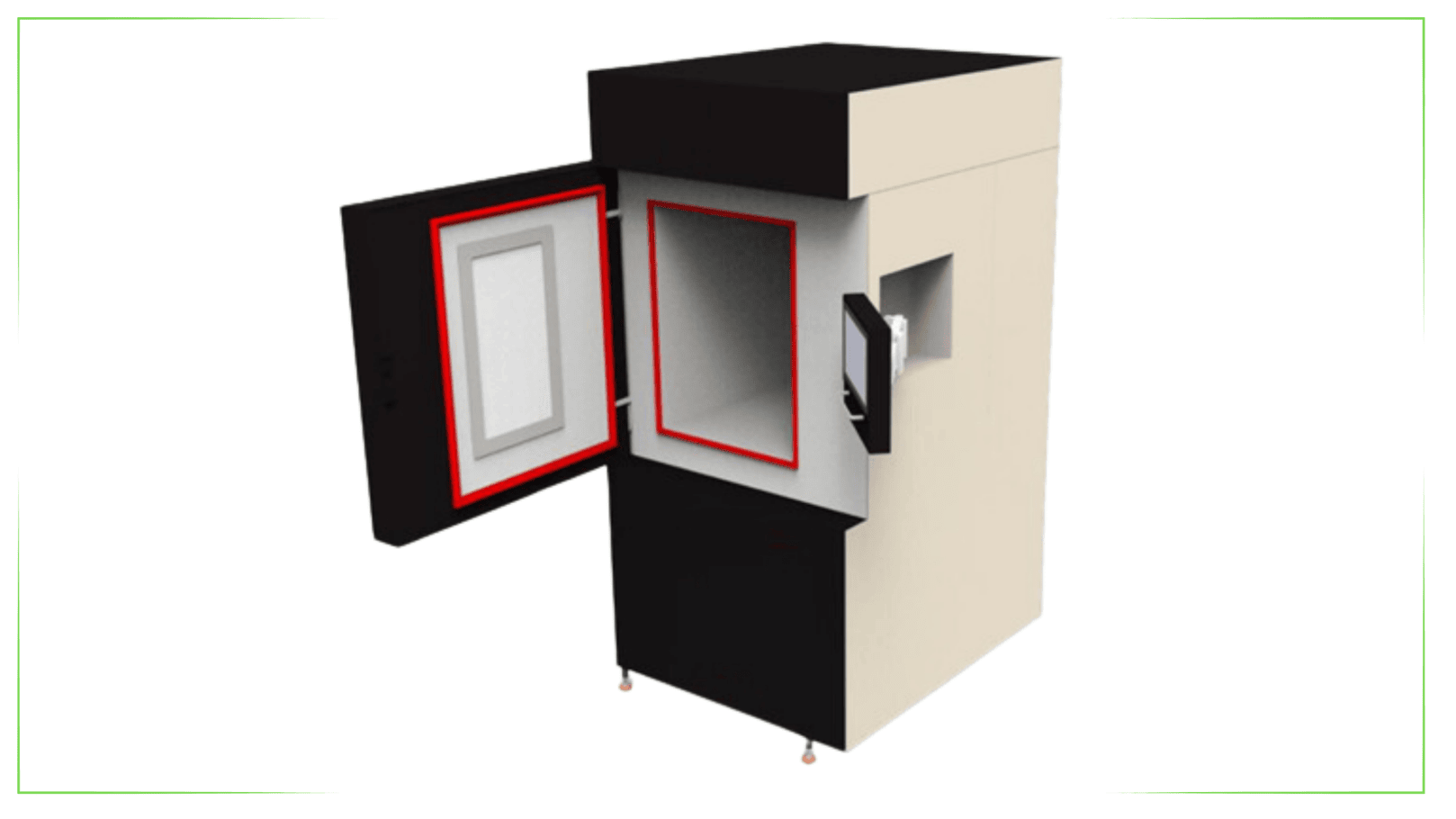

Thermal Cabinet production starts with a comprehensive design and engineering phase, during which high insulation capacity and durability are meticulously studied. The choice of materials is usually based on high-insulating composites, stainless steel and special insulation foams. After precision cutting and shaping, the assembly phase begins, where doors, windows, ventilation and control systems are added to the main structure of the cabin. Advanced electrical and control systems are integrated to provide temperature control. After assembly, the performance of the cabinet is verified through calibration and testing and subjected to strict quality control processes. The final product is packaged and delivered to the customer for installation and training.

GSR3100-X Series High Impact Resistance Hydraulic Road Blocker, ASTM M50/IWA14-1/

It is designed to meet PAS68 level impact resistance. The product successfully passed the full-scale crash test with zero penetration and maintained its operational functions after the crash. GSR-X certified according to IWA14-1:2013 standards

With its idealistic design, high quality components and first class material, Road Blockers provide maximum protection in areas requiring high level security.

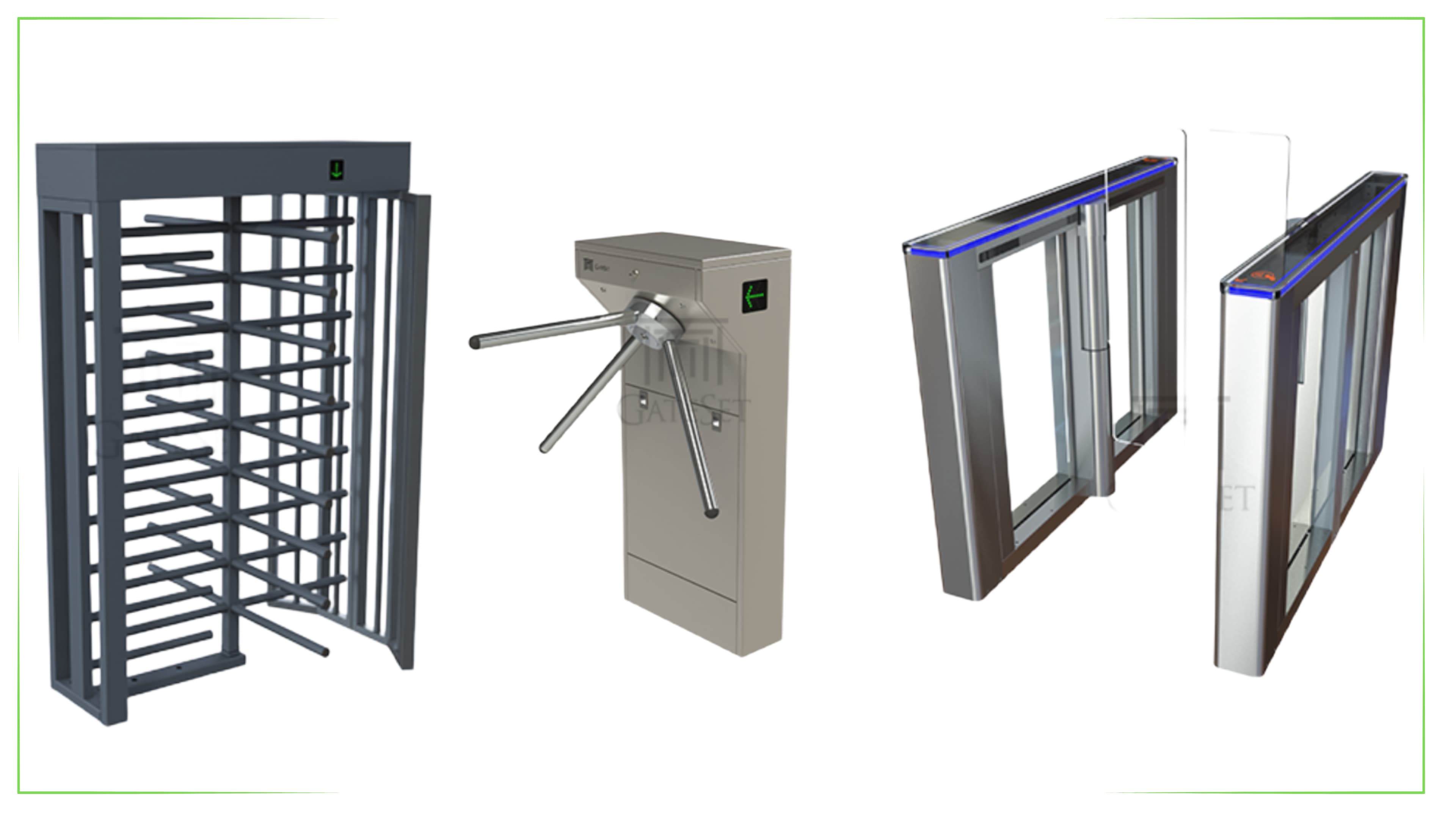

From public transportation to stadiums, business centers to industrial facilities; we offer complete solutions for pedestrian access control with a full range of turnstiles, including Waist Height Tripods for areas with moderate security, Fast Gates for business centers and government facilities where aesthetic value is important, Swing Gates and Full Turnstiles for disabled and goods access.