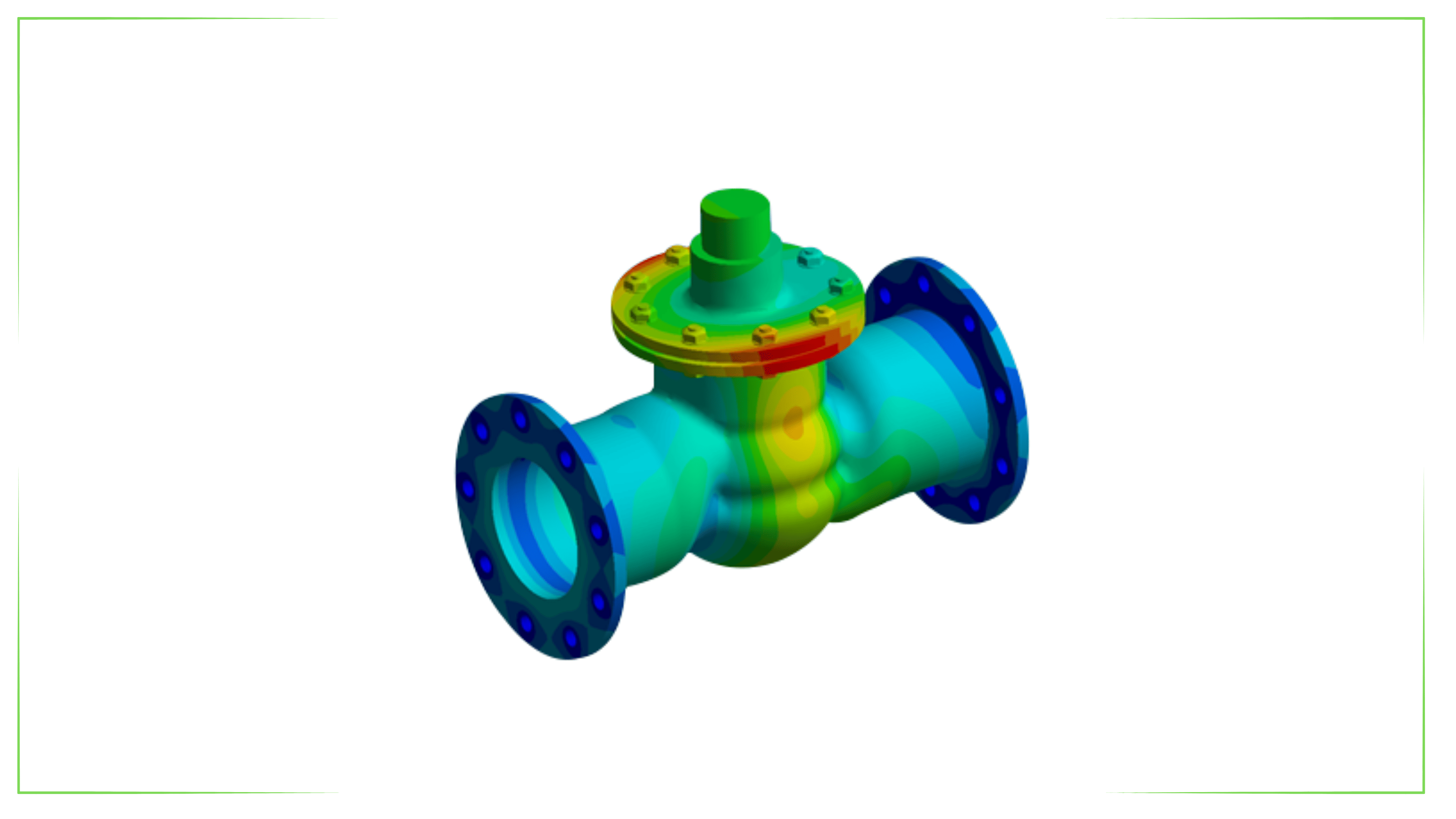

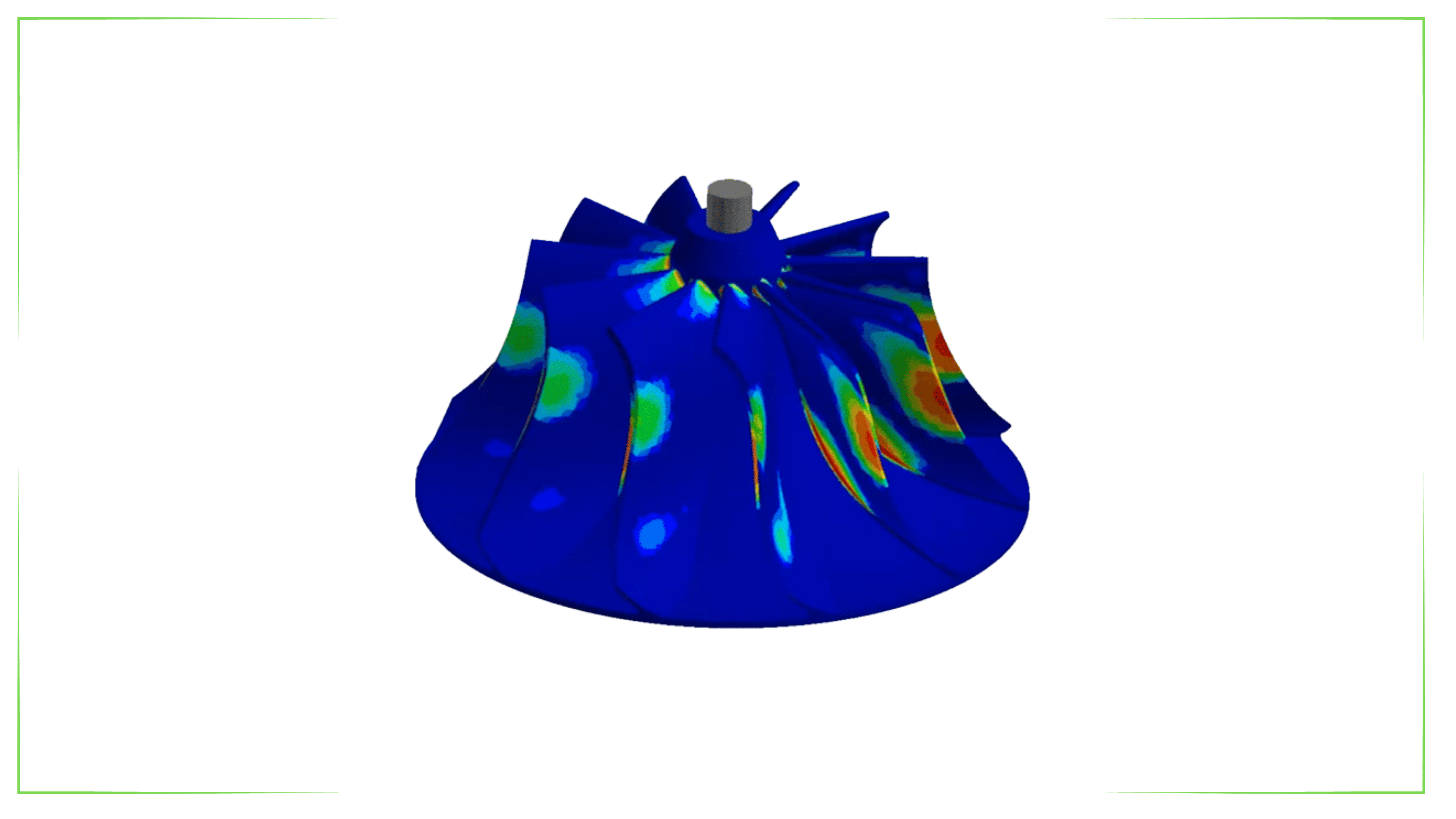

ANSYS Mechanical is a comprehensive solution for engineers and designers, offering flagship finite element analysis (FEA) software for structural, thermal, acoustic and more. It can be used for a wide range of applications, from linear statics to complex transient simulations.

Ansys LS-DYNA is industry-leading open simulation software used for applications such as drop tests, impact and penetration, bumps and crashes, occupant safety and more. You can tackle simulations involving material damage and look at how damage progresses through a part or system. Models with large amounts of interacting parts or surfaces are also easily handled, and load transfer between interactions and complex behavior is accurately modeled. Using computers with a higher number of CPU cores can significantly reduce solution times.

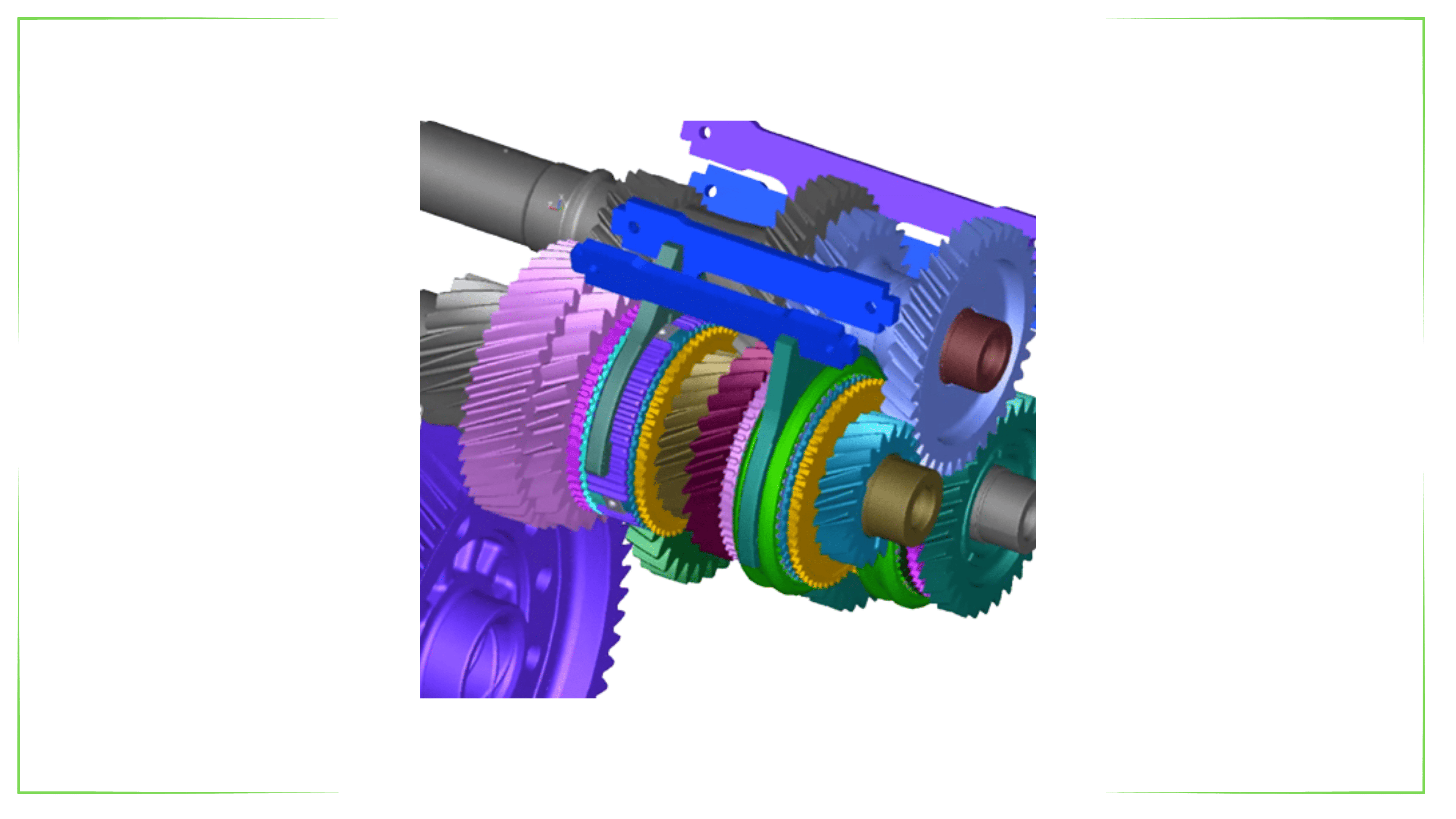

Ansys Motion is a third generation advanced many-body dynamics solver. It provides an integrated simulation environment for system components and systems. It provides fast and highly accurate kinematic analysis of both rigid and flexible bodies in a single solver. It also includes motion performance of systems, safe stress calculations, heat transfer problems, vibration and fatigue analysis. In large assemblies, flexibility and contact effects can be analyzed with millions of degrees of freedom. A model created can be used repeatedly for different types of simulations.

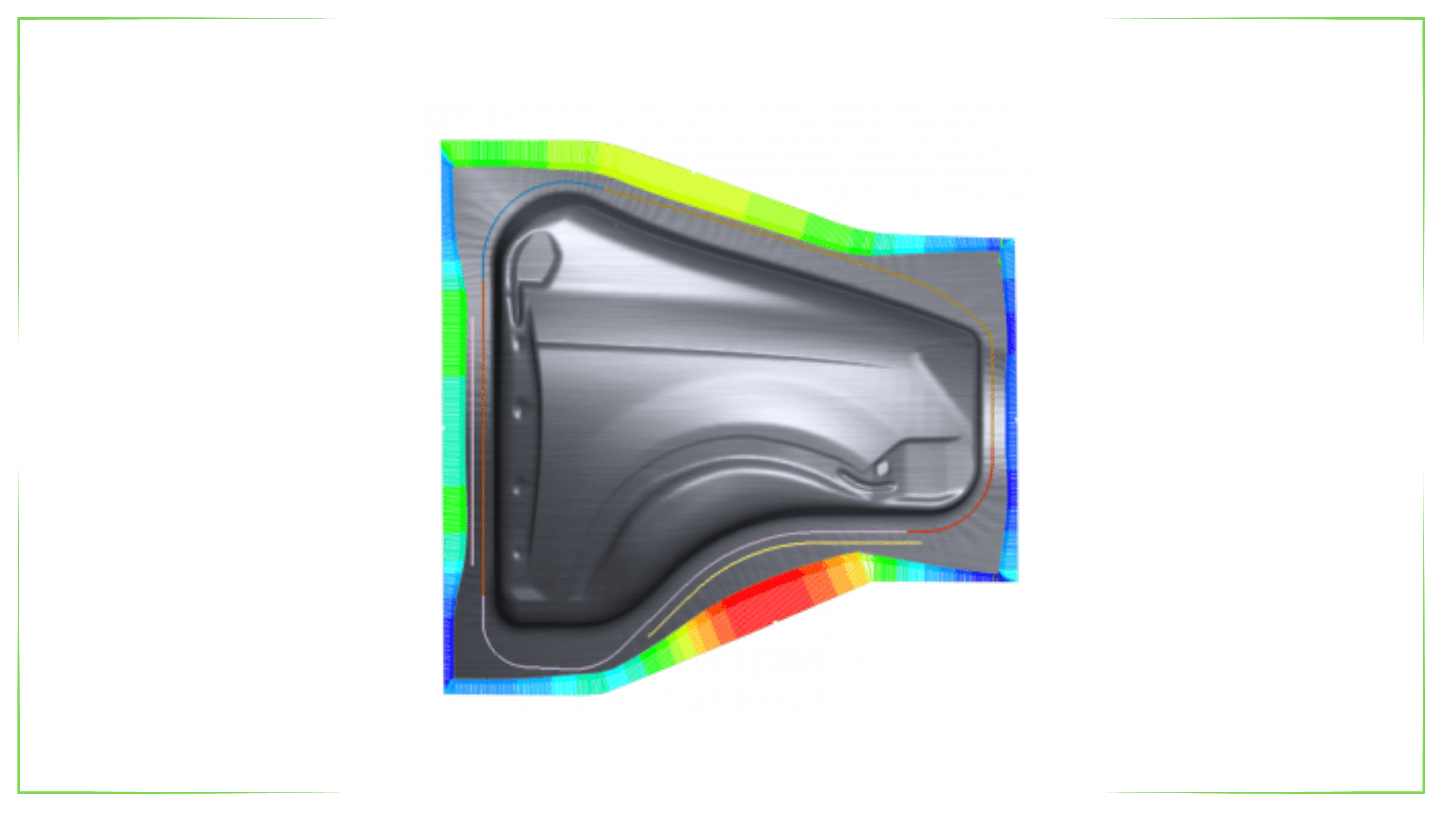

Ansys Forming simulates the sheet metal forming process with an end-to-end workflow. Thanks to its high-speed solver, it allows all mold operations to be performed on a single platform with a user-friendly interface. Ansys Forming reduces die cutting and design time in your production improvement processes and cost saving efforts with its solution speed and high result accuracy. It allows you to examine applicability, formability and springback during sheet metal forming. Using the LS-DYNA solver, Ansys Forming is a comprehensive platform to observe all stages of the sheet metal forming process.

Ansys nCode DesignLife integrates with Ansys Mechanical to reliably assess fatigue life. Using finite element analysis (FEA) results from the Ansys Mechanical and Ansys LS-DYNA solvers, it calculates stresses and strains, then determines the predicted life of a product. It allows the impact of different materials and alternative geometries on the predicted lifetime to be seen quickly and design variables to be optimized according to the desired product lifetime before the prototyping phase or testing process begins. Fully integrated into Ansys Workbench for ease of use and seamless workflow.