Additive Manufacturing

The rapid advancement of technology paves the way for innovations in the production sector as in every field. Parts that used to be produced with traditional methods can now be produced more easily, quickly and cost-effectively with new generation manufacturing techniques, also known as additive manufacturing or 3D printing. In this article, we will examine the three different production methods offered by additive manufacturing and which methods should be used for which materials according to ASTM 52900 standards.

What is Additive Manufacturing?

Additive manufacturing is a production method that works on the principle of adding material layer by layer. Three-dimensional objects are produced from a digital model using various materials such as plastic, metal and ceramics. This method offers many advantages compared to traditional manufacturing methods:

Less material waste: Additive manufacturing uses only as much material as needed. This results in significant material savings compared to traditional methods.

Faster production: Even parts with complex geometries can be produced quickly with additive manufacturing. This shortens the prototyping process and accelerates product development.

Reduced costs: In low-volume production, additive manufacturing offers a more cost-effective solution than traditional methods.

More design freedom: Additive manufacturing enables the production of parts with complex geometries and internal structures, giving designers more freedom.

Part production with Additive Manufacturing can be realized in 3 different ways:

1. Production of Spare Parts for a Part Produced by Traditional Method: In this method, the original design of a failed part is preserved and the spare part is produced quickly. It is especially useful for mass production parts and in emergency situations.

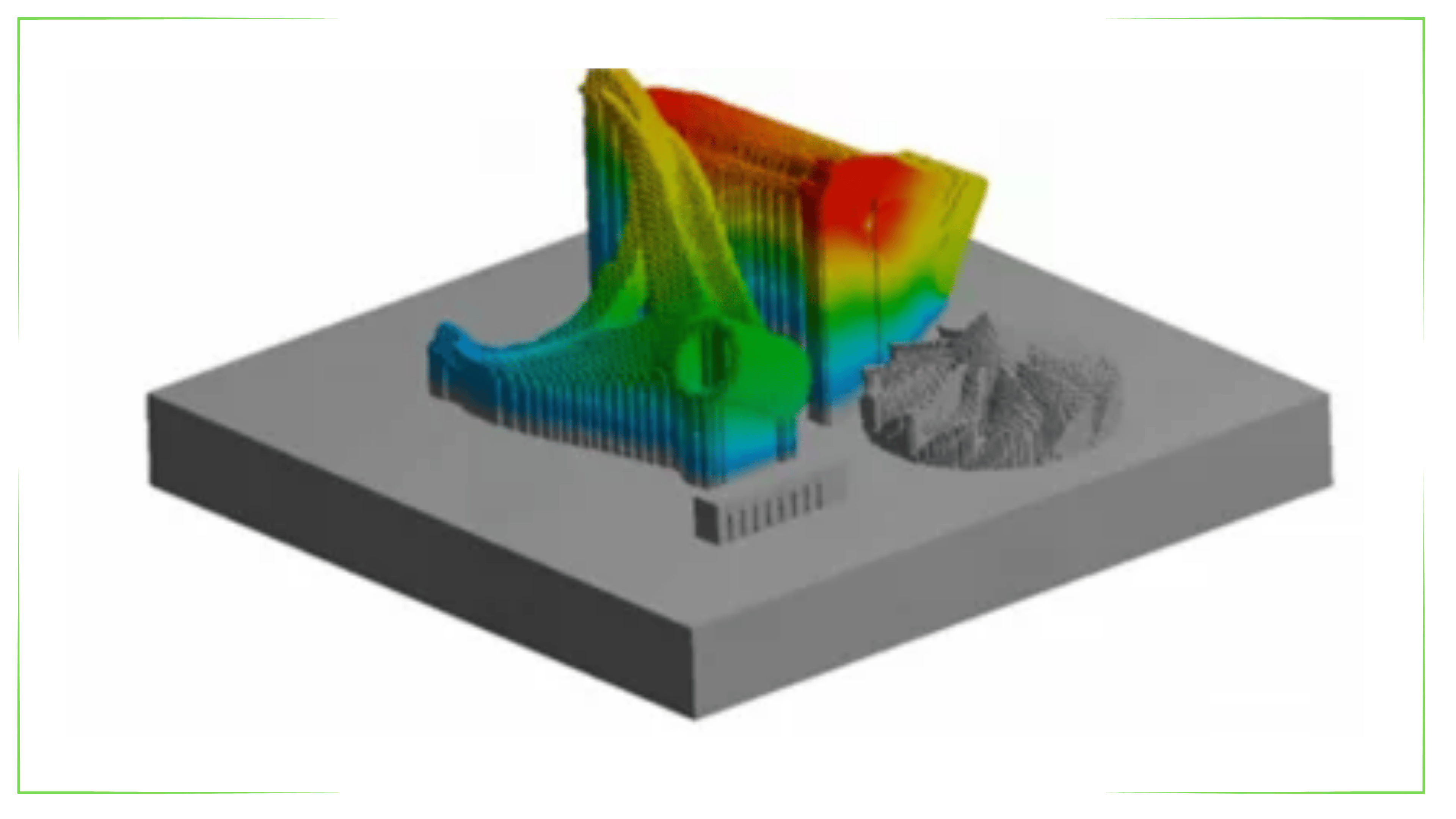

2. Adaptation of a Part Produced by Traditional Method for Eİ: In this method, the design of an existing part is optimized to take advantage of the benefits of additive manufacturing. While maintaining the function and working principle of the part, modifications can be made to save weight or make it easier to assemble.

3. New Design According to the EI Method: In this method, the part is completely designed taking into account the possibilities offered by additive manufacturing. The function of the part is determined and designed according to the advantages of the Eİ method such as lightness, fewer parts and ease of assembly.

Which material can be used with which method?

There are a wide variety of materials that can be used in additive manufacturing. The most commonly used materials include plastics, metals, resins and ceramics. ASTM 52900 standards specify which additive manufacturing method should be used for each material. This standard ensures that the most appropriate method is selected, taking into account the mechanical and chemical properties of the material, production parameters and post-production processes.