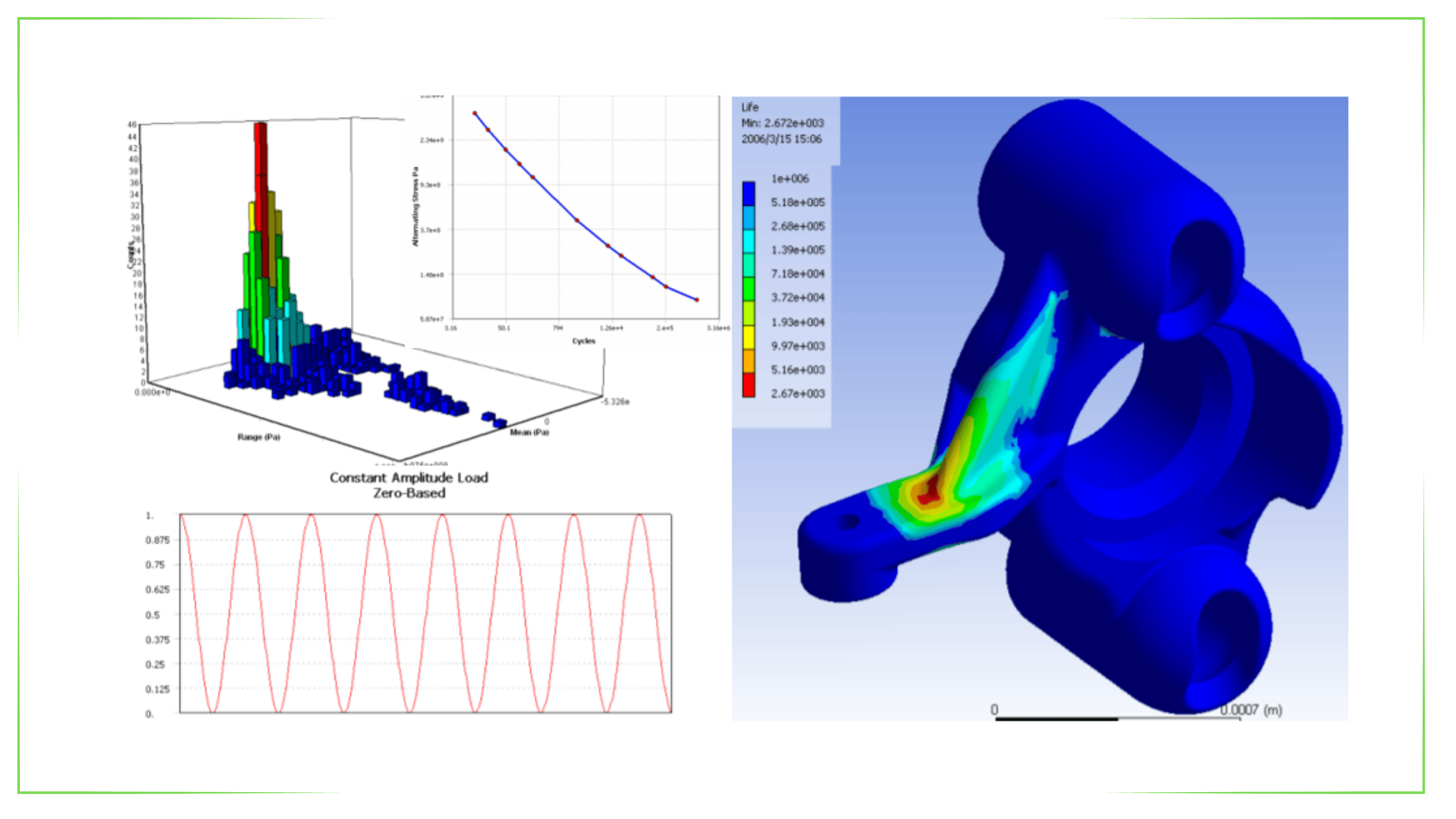

Fatigue Analysis

Structures subjected to repeated loads may be subjected to a damage mechanism called fatigue over time. This damage, although invisible at first, can reach a critical point when a certain number of loads and cycles are reached, leading to structural failure.

Fatigue analysis is an important engineering tool used to determine how many loads and cycles structures subjected to repeated loading can withstand. Through this analysis, engineers can detect the first signs of fatigue damage, determine critical load and cycle values, and create safer and more durable designs.

Three basic methods used in fatigue analysis:

1. Stress Life: This method is used to determine the number of loads and cycles at which fatigue damage reaches a critical stress level. This method is suitable for structures with simple geometries and subjected to relatively low loads.

2. Strain Life: This method is used to determine the number of loads and cycles at which fatigue damage reaches a critical strain level. More complex than the stress life method, it is suitable for structures with more complex geometries and subjected to higher loads.

3. Fracture Mechanics: This method is an engineering discipline that studies the formation, growth and ultimate failure of fatigue cracks. Fracture mechanics is used to determine the critical fatigue crack size and the number of loads and cycles required for this size to occur. This method is used for aircraft wings, pressure vessels and other critical structures that are highly susceptible to critical fatigue damage.

Benefits of fatigue analysis:

Helps design safer and more durable structures.

Helps predict structural failures.

Helps reduce repair and maintenance costs.

Enables more economical designs with lighter weight and less material usage.